### The Quest for Oxygen Production on the Moon

In an era where lunar exploration is steadily increasing, the need for sustainable living on the Moon has become more urgent. A crucial component in making lunar bases viable is the production of oxygen, which is not only required for astronauts’ survival but also for creating fuel for rocket systems aimed at Mars and beyond. Recent advancements have been made by Sierra Space, a private aerospace firm focused on developing technology capable of producing oxygen from lunar resources.

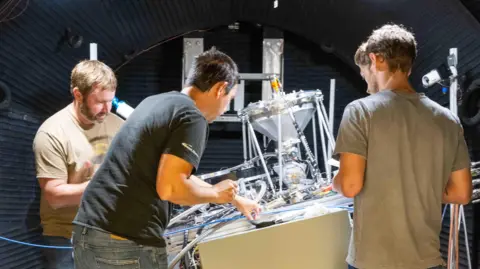

At NASA’s Johnson Space Center, Sierra Space has been conducting experiments utilizing a specially-designed machinery aimed at simulating lunar conditions. Inside a large spherical chamber, engineers examined their high-tech apparatus consisting of a metallic device surrounded by colorful wiring. This contraption is intended to convert lunar regolith— a dust-like material found on the Moon’s surface— into breathable oxygen. The testing involved heating the regolith to temperatures exceeding 1,650°C, after which, through a series of chemical reactions aided by reactants, oxygen-containing molecules began to escape into the atmosphere.

### Moving Beyond Earth-Based Testing

According to Brant White, a program manager at Sierra Space, they have made significant progress with Earth-based testing and are ready to move on to lunar trials. This is particularly important as future lunar missions will require a reliable supply of oxygen not just for respiration but also as an oxidizer for rocket fuel intended for ambitious missions to Mars. To underline the cost-effectiveness of extracting oxygen on the Moon, White highlighted the exorbitant expenses associated with transporting oxygen from Earth. He emphasized that developing on-site production technology could save hundreds of millions of dollars in mission costs.

To make this dream a reality, Sierra Space is working on a carbothermal reduction process that effectively gets oxygen from the regolith’s metal oxides. However, extracting oxygen on the Moon’s surface presents unique challenges. High temperatures cause the regolith to behave differently in the absence of Earth-like gravity, and the abrasive nature of lunar dust can wear out equipment rapidly. Tests conducted in a vacuum to simulate low gravity revealed the necessity of designing technology capable of overcoming these hurdles.

### Challenges of Lunar Production

A critical issue highlighted by researchers, including Paul Burke from Johns Hopkins University, centers around the gravity on the Moon. Computer simulations have indicated that certain oxygen extracting technologies, such as molten regolith electrolysis, may struggle to function efficiently due to the Moon’s weak gravitational force. This technique involves using electricity to separate oxygen from lunar minerals, but the lack of gravity affects the way oxygen bubbles behave in the molten regolith, slowing their release.

Nonetheless, various strategies could be implemented to overcome these difficulties. For instance, utilizing a vibrating mechanism to agitate the oxygen-producing devices may assist in helping bubbles detach more easily. Sierra Space’s process presents an advantage in this context, as the generated bubbles rise freely instead of sticking to an electrode surface, thereby minimizing production delays.

### The Future of Oxygen Production

In terms of logistics, Burke estimates that each astronaut might require upwards of two to three kilograms of regolith on a daily basis to produce sufficient oxygen. However, life support on a lunar base could potentially recycle exhaled oxygen, reducing the total amount of regolith needed. Moreover, the primary opportunity for oxygen extraction technologies could lie in fulfilling the oxidizer requirements for rocket fuel, empowering more extensive exploratory missions into the solar system.

Palak Patel, a PhD student at the Massachusetts Institute of Technology, has been focusing on methodologies to extract both metal and oxygen from lunar soil, aligning with Minnesota’s goal of minimizing resupply missions from Earth. One innovative approach involves utilizing sound waves to help dislodge oxygen bubbles formed on electrodes in low gravity, thus counterbalancing the challenges introduced by lunar conditions.

The exploration of lunar regolith holds immense potential. With innovative technologies, astronauts could create not only oxygen but also metals like iron and titanium, laying the groundwork for 3D printing necessary components and structures directly on the Moon. This capability emphasizes the importance of developing self-sustaining systems for future lunar habitats, reducing dependency on Earth while paving the way for deeper space travel. Achieving these technological advancements could turn the Moon into a hub for future human exploration, setting the stage for humanity’s next great leap into the cosmos.